New White Paper released

White Paper 2: Does powder quality really impact LPBF performance?

- About us

- Newsroom

March 21, 2025

AM Forum Berlin : Two insightful days of networking and discussions with SAM

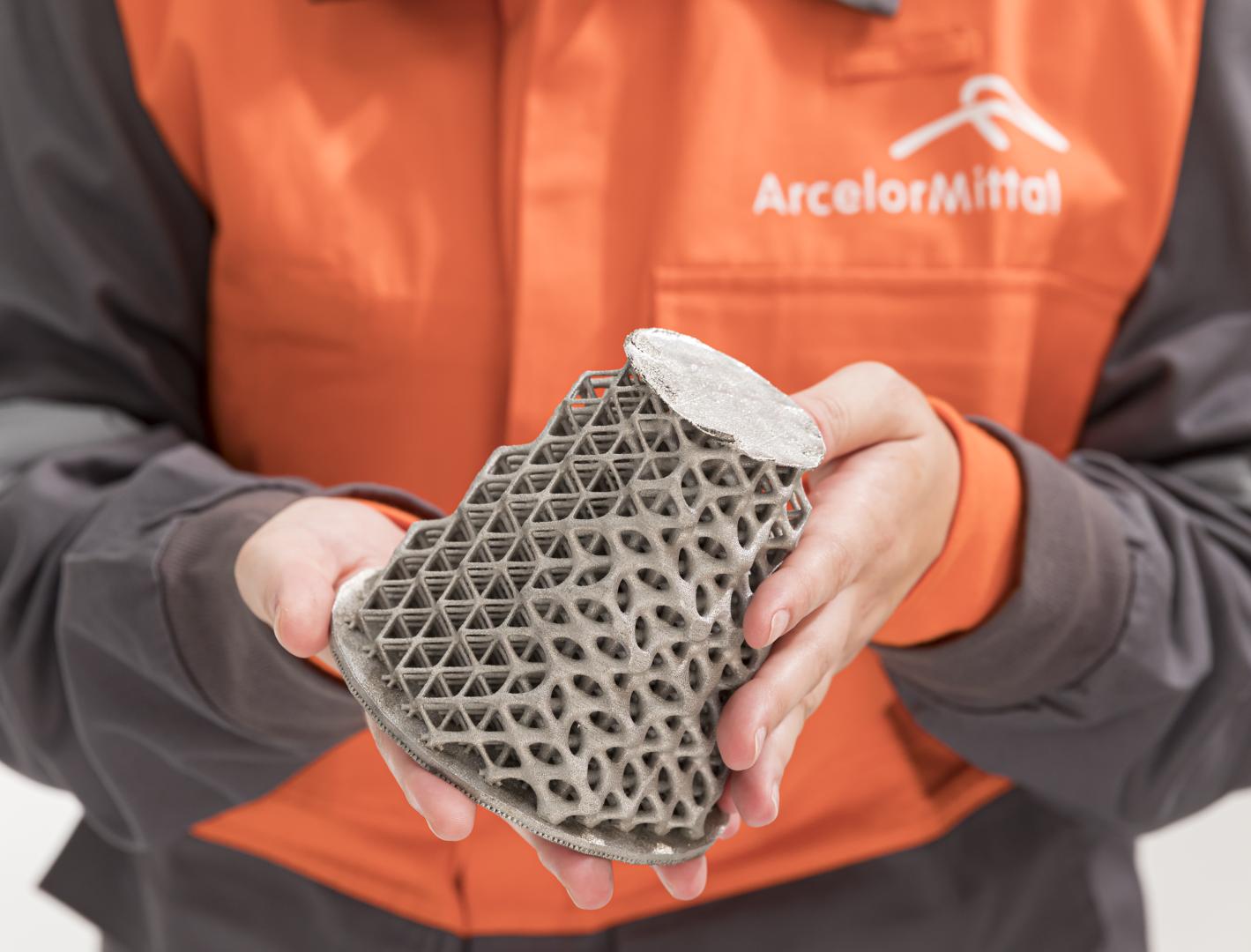

At ArcelorMittal Powders we were thrilled to have participated in this annual event, grabbing the opportunity to showcase the importance of Steel Additive Manufacturing.

Find out more

News

March 20, 2025

Steel Additive Manufacturing in ArcelorMittal Gent Blast Furnace

At ArcelorMittal Gent the operating life of the Blast Furnace has increased dramatically over time, reaching 39 million tonnes until the last relining, by avoiding dangerous leakages in daily operations.

Find out more

News

February 28, 2025

Legacy and future at Zdzieszowice. Poland

Our Chief Marketing Officer, Aubin Defer, along with key members of the ArcelorMittal Powders team, Elias Domingo and Yusuf Üzümcü, recently had the opportunity to delve into the innovative practices at ArcelorMittal Poland’s flagship coking plant. This visit was an enlightening experience, showcasing how the reliability engineers at the plant are pioneering the use of Steel Additive Manufacturing.

Find out more

News

January 28, 2025

Our CEO, Colin Hautz, featured on 3Dprint.com

Ahead of Additive Manufacturing Strategies 2025 conference in New York, in this article on 3DPrint.com, our CEO, Colin Hautz, reflects on the issues facing Steel Additive Manufacturing (SAM) and how it is influencing ArcelorMittal’s approach to additive.

Find out more

News

December 05, 2024

ArcelorMittal enhances production reliability with Steel Additive Manufacturing

At ArcelorMittal, Steel Additive Manufacturing (SAM) is used to keep critical parts working. For example, for sensors that are crucial to controlling our product quality. SAM consistently delivers on process quality and reliability, making it a proactive option for optimisation, not simply a last resort for obsolete parts or supply issues.

Find out more

News

November 26, 2024

Formnext 2024, a great success!

From November 19th to 22nd, ArcelorMittal Powders participated in Formnext (Frankfurt, Germany), the world's largest additive manufacturing trade fair. Our 100-square-meter booth featured distinct areas showcasing the contributions of Steel Additive Manufacturing.

Find out moreNews

November 12, 2024

ArcelorMittal and HP Announce Strategic Collaboration to Advance Additive Manufacturing

ArcelorMittal, a global leader in sustainable steel solutions, and HP, a renowned printing company with extensive expertise in additive manufacturing, are pleased to announce a strategic collaboration to advance the field of steel additive manufacturing. This collaboration marks a significant milestone in developing innovative solutions that will shape the future of additive manufacturing.

Find out more

News