Steel Additive Manufacturing in ArcelorMittal Gent Blast Furnace

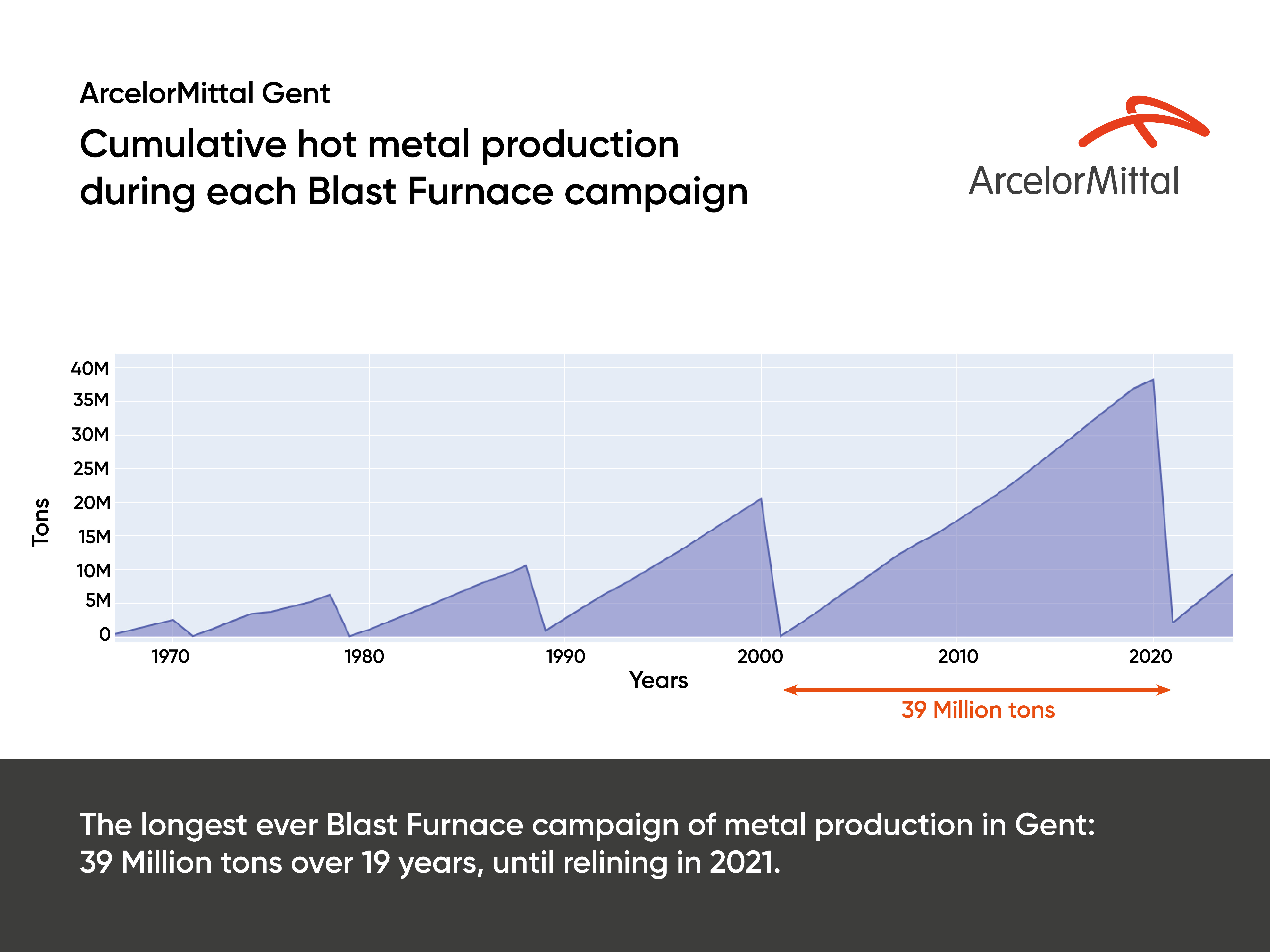

At ArcelorMittal Gent the operating life of the Blast Furnace has increased dramatically over time, reaching 39 million tonnes until the last relining, by avoiding dangerous leakages in daily operations.

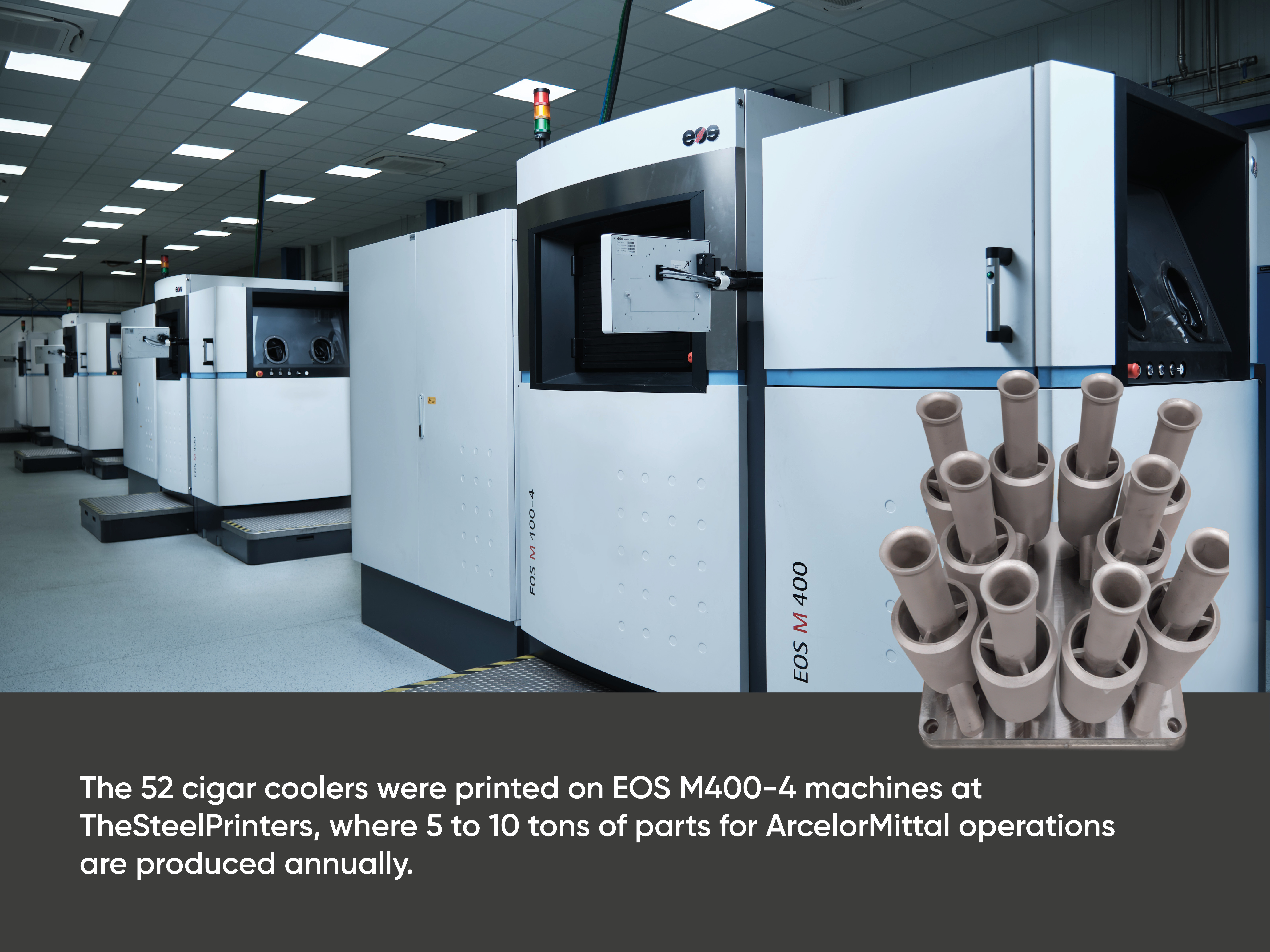

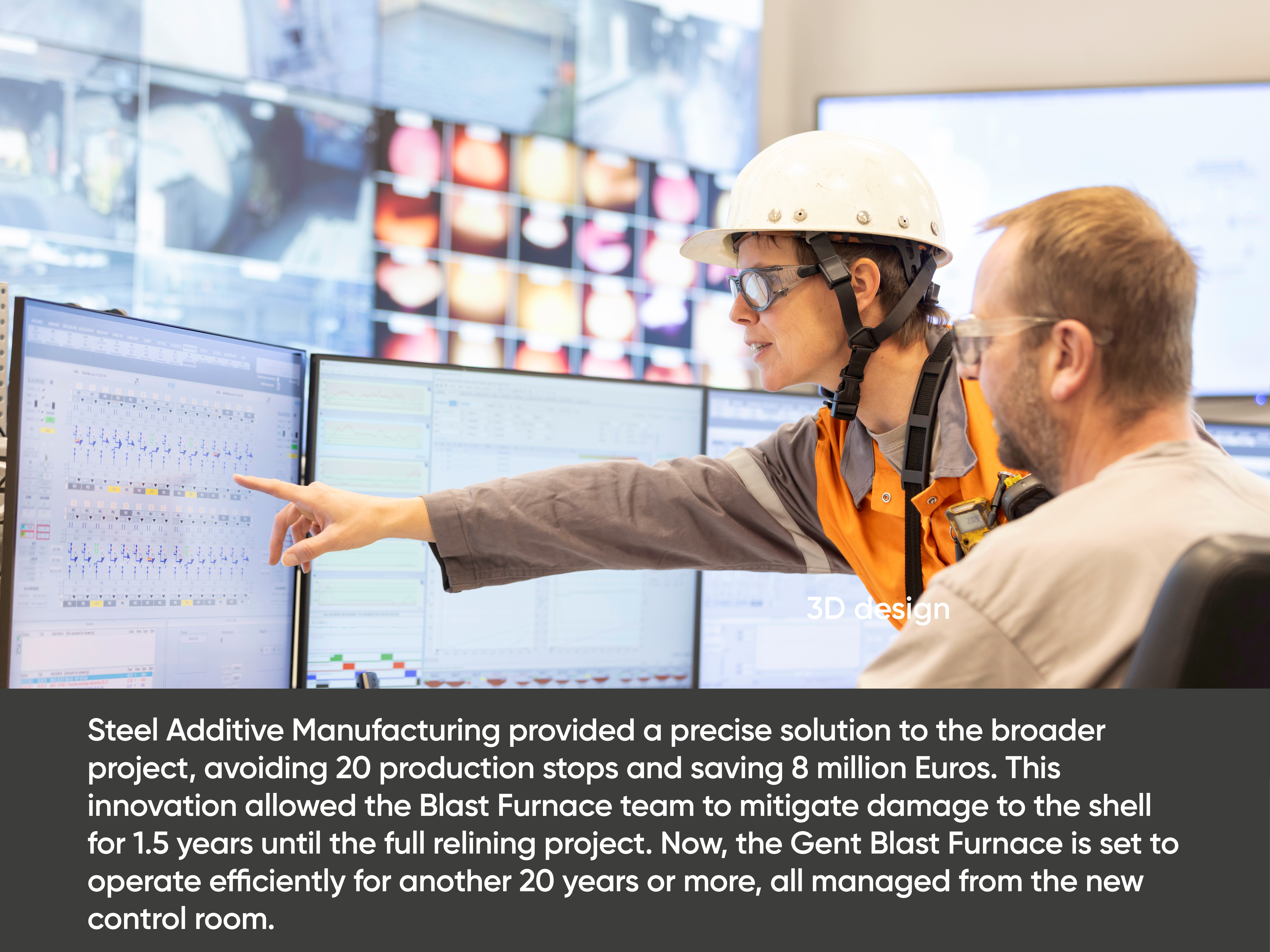

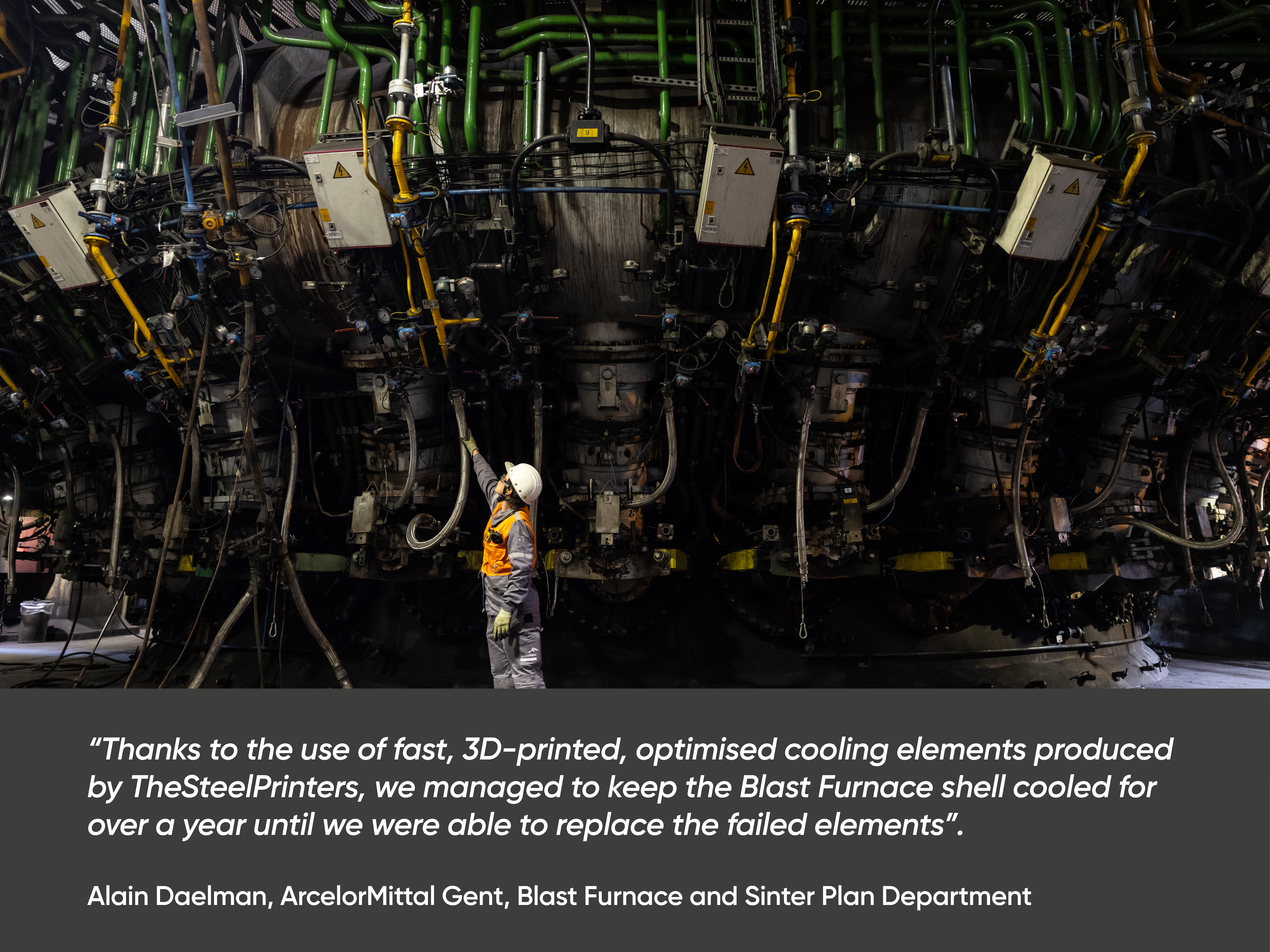

Steel Additive Manufacturing (SAM) has played a critical role in this. ArcelorMittal's engineering and Global R&D teams developed an innovative concept to provide precise cooling of the furnace shell, extending the safe operation by one and a half years. The parts were produced by TheSteelPrinters, ArcelorMittal's joint venture in the production of spare parts by Additive Manufacturing.

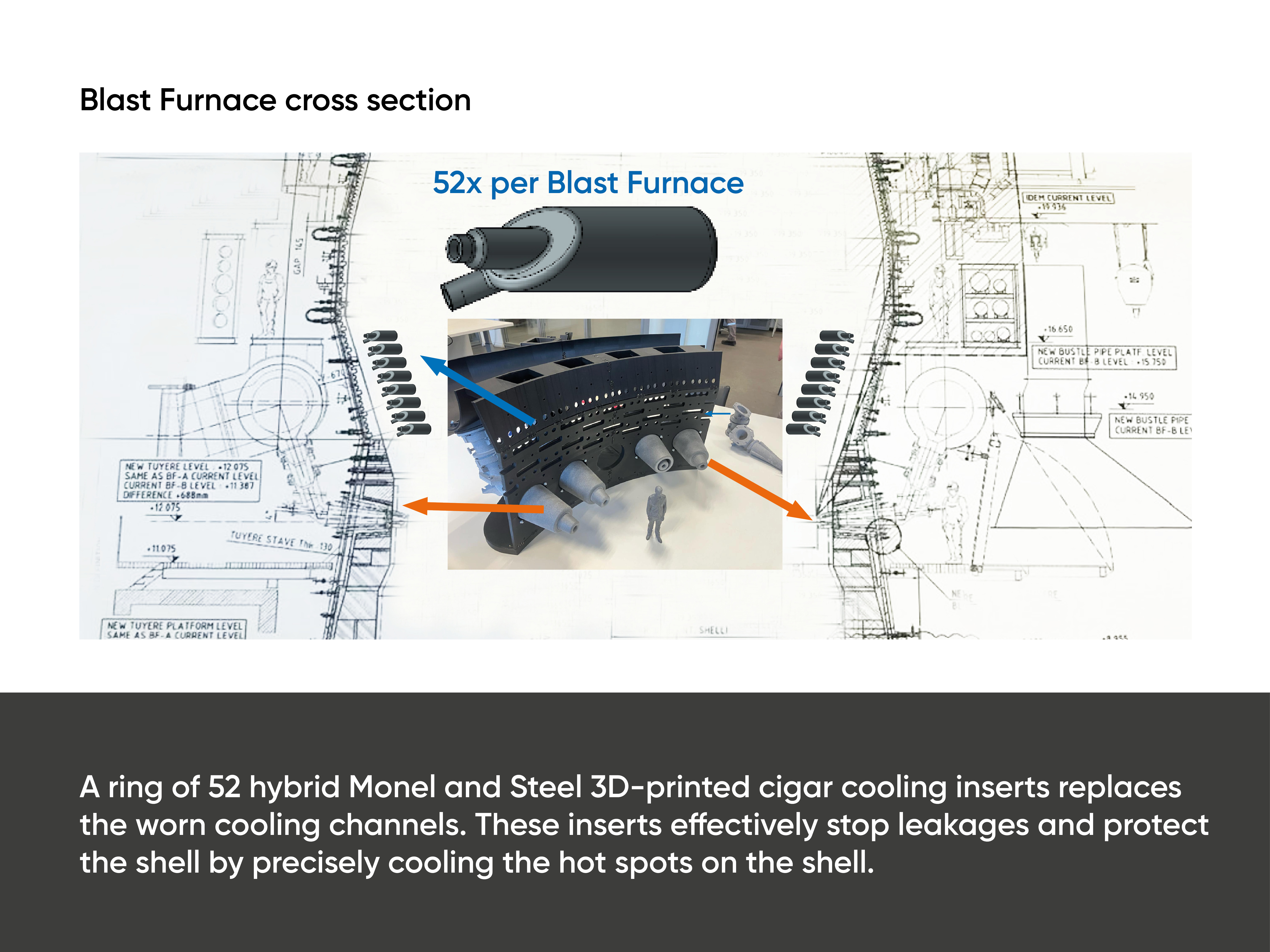

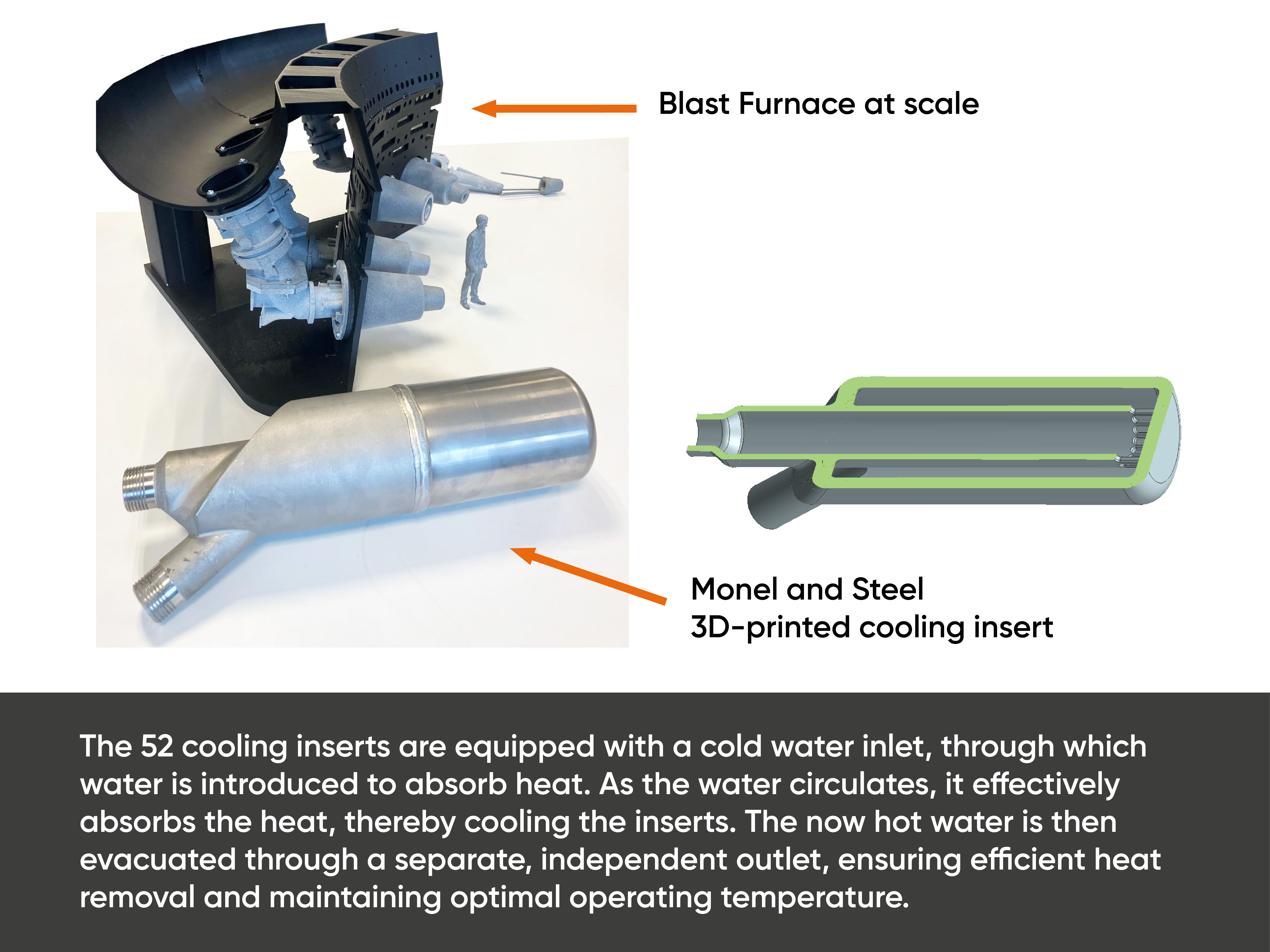

A ring of fifty-two, 3D-printed, metallic water-cooling inserts was channelled through the Blast Furnace shell, providing surgical conformal cooling on a gigantic scale.

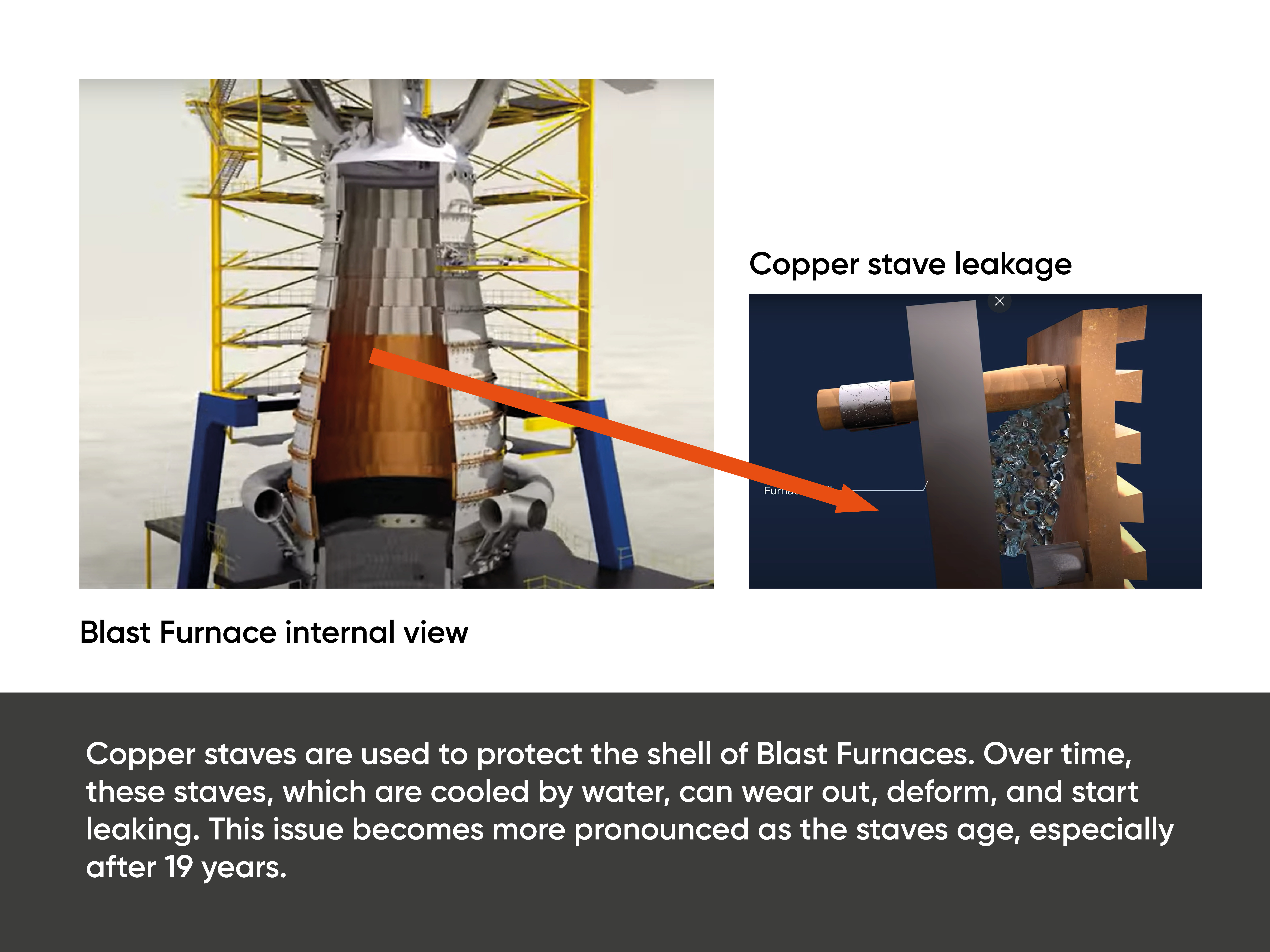

These inserts replaced the worn cooling channels of the copper staves (large copper armour plates) that traditionally protect the Blast Furnace shell. Exposed to extreme temperatures, the 3D-printed inserts compensated the reduced heat extraction capacity of the staves and maintained the structural integrity of the Blast Furnace shell, mitigating damage for 1.5 years until the full relining could be completed.

Together with Aubin Defer, Michaël de Vos, Leander Van Speybroeck, and Bram Verlooye, here are a few highlights of this endeavour at the brand-new Gent’s Blast Furnace control room.

|  |

|  |

|  |

|  |

21 March 2025