AdamIQ M300

AISI 18Ni300 | W. Nr 1.2709 | DIN X3NiCoMoTi 18-9-5 | UNS K93120

Our M300 maraging steel is the right “tooling purpose” powder for applications that need to balance printability, hardness and toughness. This alloy is typically used in inserts for conformal-cooling of molds in Hot Stamping, Plastic Injection Molding, High Pressure Die Casting.

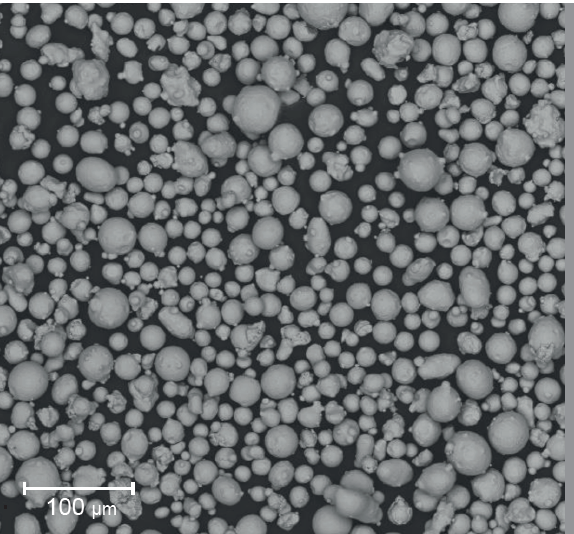

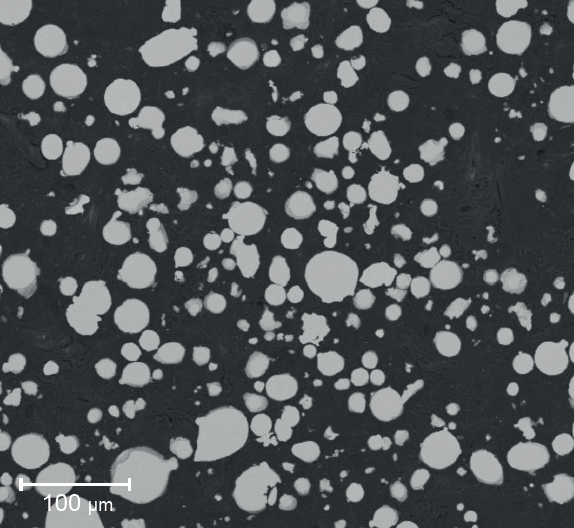

Made from 100% recycled steel and renewable energy. Spherical, with high flowability and low level of impurities.

M300 is a maraging steel that offers superior strength, hardness, and toughness, making it an excellent choice for high-performance applications. Its unique strengthening mechanisms, easy heat-treatability, and suitability for additive manufacturing processes make it a top choice for tooling, molding, aerospace, and automotive components.

After undergoing a simple thermal aging heat treatment, the built parts can achieve remarkable characteristics, including hardness higher than 50 HRC and yield strength around 2.000 MPa with excellent toughness. Moreover, the material boasts exceptional machinability to achieve required tolerances and finish. It can maintain its outstanding features even when exposed to mildly elevated temperatures of up to approximately 400 °C (752 °F).

Main applications

Tools and molds inserts

Tire sipes and molds

High-performance industrial parts

High-wear components

Markets

Aerospace

Automotive

Energy

General Industry

Oil and Gas

Powder properties

Chemical Composition in weight % (1)

| Iron | Balance | Oxygen | < 0.10 | |

| Nickel | 18.00 - 19.00 | Nitrogen | < 0.10 | |

| Cobalt | 8.50 - 9.50 | Aluminum | 0.05-0.15 | |

| Molybdenum | 4.70 - 5.20 | Carbon | < 0.03 | |

| Titanium | 0.50 - 0.80 | Sulphur | < 0.01 | |

| Manganese | < 0.10 | Phosphorus | < 0.01 | |

| Silicon | < 0.10 |

| Nominal particle range | 20-53 μm |

|---|---|

| Apparent density (2) | 4.1 g/cm3 |

| Hall flow (3) | 20 s/50g |

Also available in particle sizes:

• Less than 20 microns for Binder Jetting (BJT), Metal Injection Molding (MIM) or specific processes targeting very thin walls.

• 53-105 microns typically for Electron Beam Melting (EBM, E-PBF) and Laser Metal Deposition (LMD).

• Specific sizing can be considered under conditions.

--

(1). Composition fits A646 (Marage300)

(2). Apparent density according to ASTM B212

(3). Hall Flow according to ASTM B213

Packaging and handling recommendations

- Standard Packaging 2.9L CurTec drum from recycled and recyclable materials. Sealed, and including desiccant bag.

- 200 kg / 500 kg Flexbag

- Other tailored packaging are available under condition

Please ensure that you store the product in its original container in a dry area. Before using, gently tumble to prevent any segregation. If you have opened containers, it is recommended to store them in a drying oven or a controlled environment with low humidity to prevent any moisture pick up.

*Technical data and information are to the best of our knowledge at the time of printing. However, they may be subject to some slight variations due to our ongoing research programme on steels. Therefore, we suggest that information be verified at time of enquiry or order. Furthermore, in service, real conditions are specific for each application. The data presented here are only for the purpose of description, and considered as guarantees when written formal approval has been delivered by our company. Further information may be obtained from the address mentioned.

AdamIQ™ M300 datasheet

Our M300 maraging steel is the right “tooling purpose” powder for applications that need to balance printability, hardness and toughness. This alloy is typically used in inserts for conformal-cooling of molds in Hot Stamping, Plastic Injection Molding, High Pressure Die Casting.