Our White Papers

We share all our R&D expertise in 3D printing

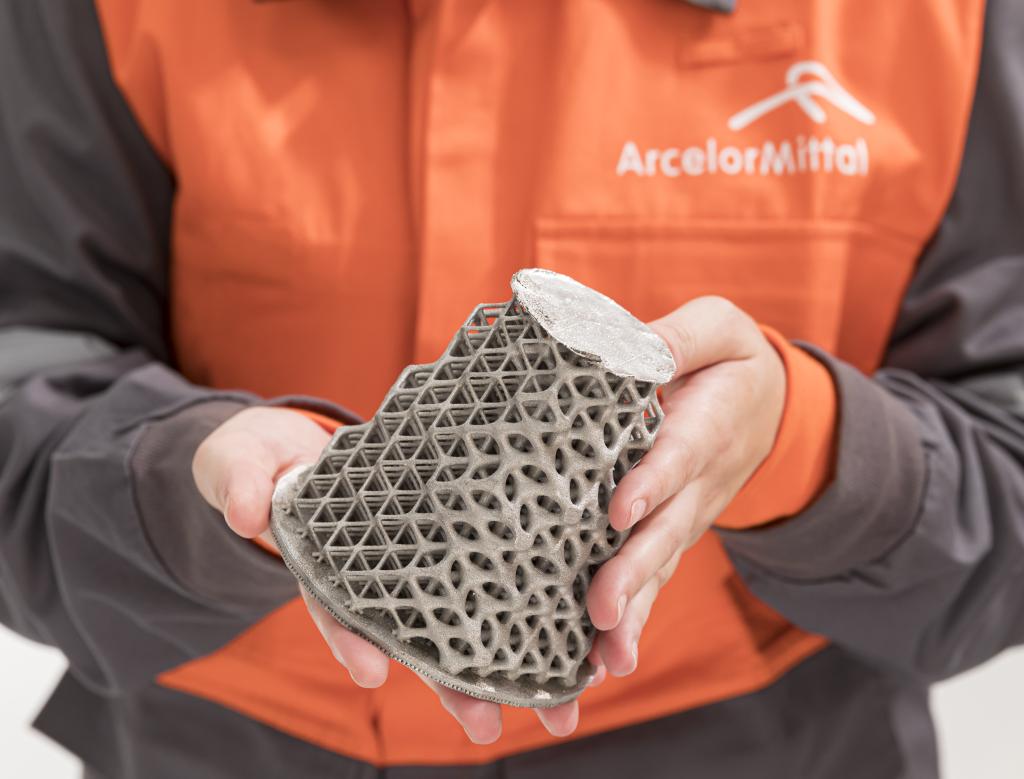

ArcelorMittal has developed a significant expertise in metal Additive Manufacturing, 3D-printing of spare parts and the technologies used to manufacture parts. Some of this expertise is shared in a series of white papers that are available below.

If you would like to find out more about the solutions created by our R&D team, please download our white papers below or contact us.

Contact our experts

Interested in learning more, collaborating on a new project, or just have questions?