AdamIQ™ 316L

AISI 316L | W. Nr 1.4404 | DIN X2CrNiMo17-12-2 | UNS S31603

AdamIQ™ 316L is a robust feedstock for any laser powder bed fusion machine (L-PBF). The “general purpose” powder suitable for the widest range of applications, across multiple industries.

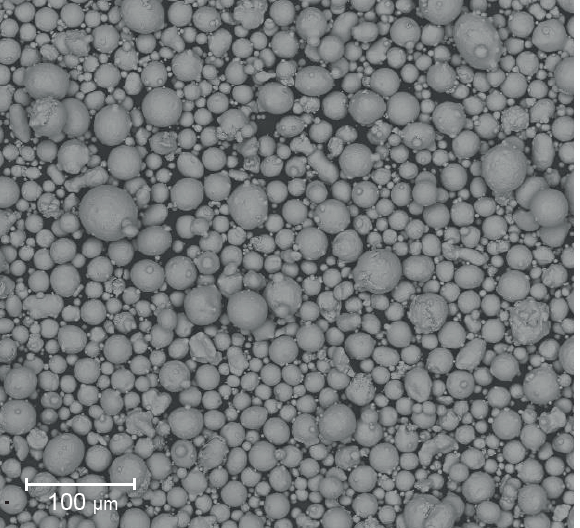

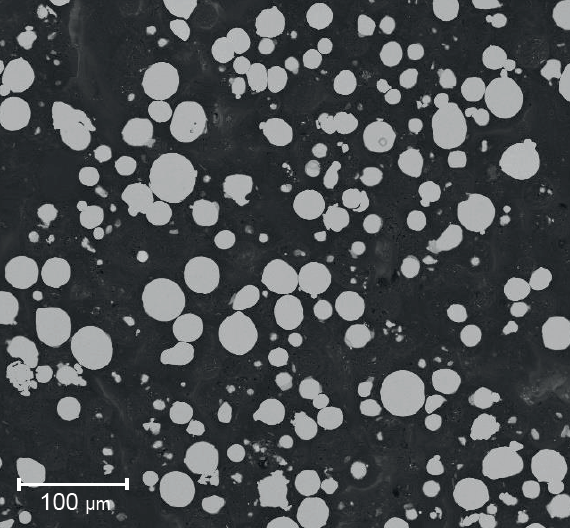

Made from 100% recycled steel and renewable energy. Spherical, with high flowability and low level of impurities.

Inert gas atomised Stainless Steel Powder, it comprises chromium, nickel, and molybdenum with an austenitic microstructure, which is particularly used for applications requiring intergranular corrosion resistance. It has excellent weldability in laser and electron-beam additive manufacturing processes. Solution annealing can improve its corrosion resistance. Most situations do not require solution annealing, which is application specific.

Post-processing methods include traditional machining, abrasive flow machining, shot peening, grinding, polishing, chemical milling/etching, and others. Parts made from 316L generally have service temperatures of up to 425 °C (800 °F), beyond which chromium carbides precipitate. Maximise your printer’s uptime by keeping it loaded and running with this versatile powder.

Main applications

Prototyping and accessories

Fixtures and heat exchangers

Instrumentation devices

Valves

Pumps and impellers

Manifolds

Tooling

Spare parts

Spray Coating and Cladding

Markets

Automotive

Aerospace

Consumer goods

Energy

Food machinery

Transportation

Powder properties

AdamIQ™ 316L

Chemical Composition in weight % (1)

| Iron | Balance | Nitrogen | < 0.10 | |

| Chromium | 16.00 - 18.00 | Oxygen | < 0.10 | |

| Nickel | 10.00 - 14.00 | Phosphorus | < 0.045 | |

| Molybdenum | 2.00 - 3.00 | Carbon | < 0.03 | |

| Manganese | < 2.00 | Sulphur | < 0.03 | |

| Silicon | < 1.00 |

| Nominal particle range | 20-53 μm |

|---|---|

| Apparent density (2) | 4.1 g/cm3 |

| Hall flow (3) | 20 s/50g |

Also available in particle sizes:

• Less than 20 microns for Binder Jetting (BJT), Metal Injection Molding (MIM) or specific processes targeting very thin walls.

• 53-105 microns typically for Electron Beam Melting (EBM, E-PBF) and Laser Metal Deposition (LMD).

• Specific sizing can be considered under conditions.

--

(1). Composition fits ASTM F3184

(2). Apparent density according to ASTM B212

(3). Hall Flow according to ASTM B213

Packaging and handling recommendations

- Recycled and recyclable drum from CurTec (minimum 2.9 L / 10 kg). Sealed, includes desiccant bag.

- Big bag solutions available on demand.

Ensure that you store the product in its original container in a dry area. Before using, gently tumble to prevent any segregation. If you have opened containers, it is recommended to store them in a drying oven or a controlled environment with low humidity to prevent any moisture pick up.

*Technical data and information are to the best of our knowledge at the time of printing. However, they may be subject to some slight variations due to our ongoing research programme on steels. Therefore, we suggest that information be verified at time of enquiry or order. Furthermore, in service, real conditions are specific for each application. The data presented here are only for the purpose of description, and considered as guarantees when written formal approval has been delivered by our company. Further information may be obtained from the address mentioned.

AdamIQ™ 316L datasheet

AdamIQ™ 316L is a robust feedstock for any laser powder bed fusion machine (L-PBF). The “general purpose” powder suitable for the widest range of applications, across multiple industries.