Chemical laboratory

An open lab for innovation!

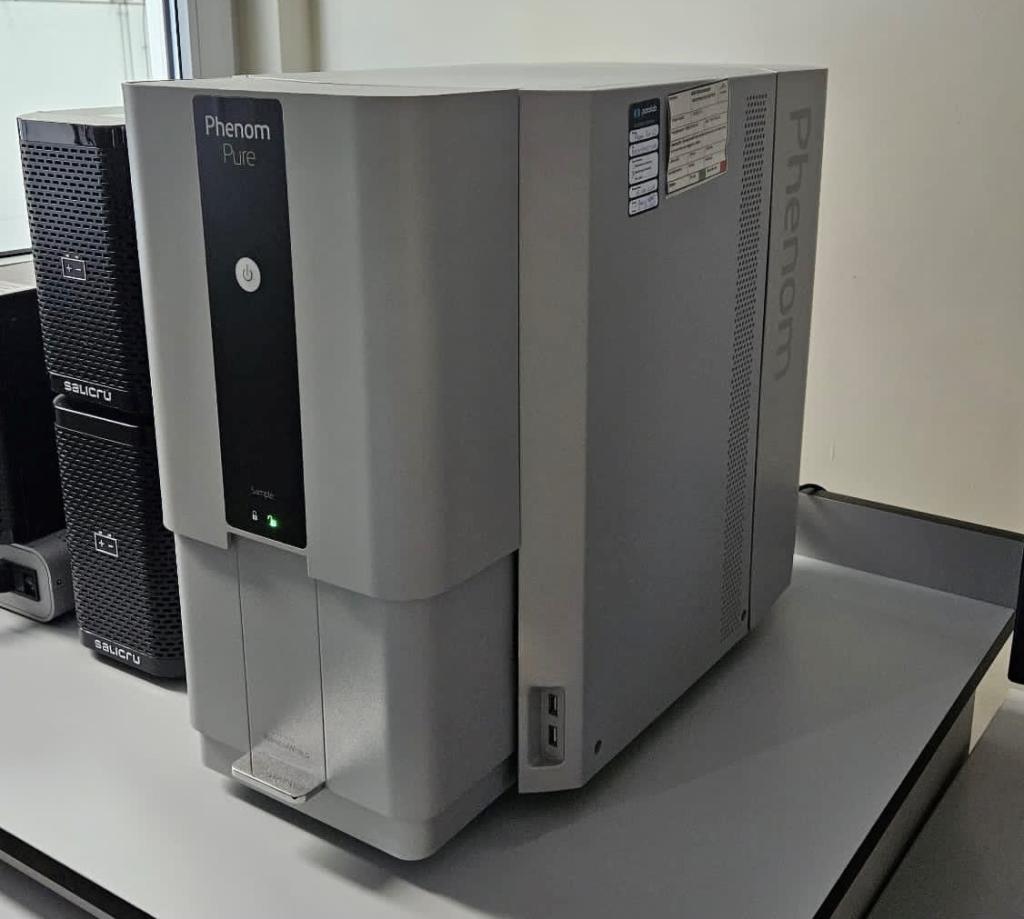

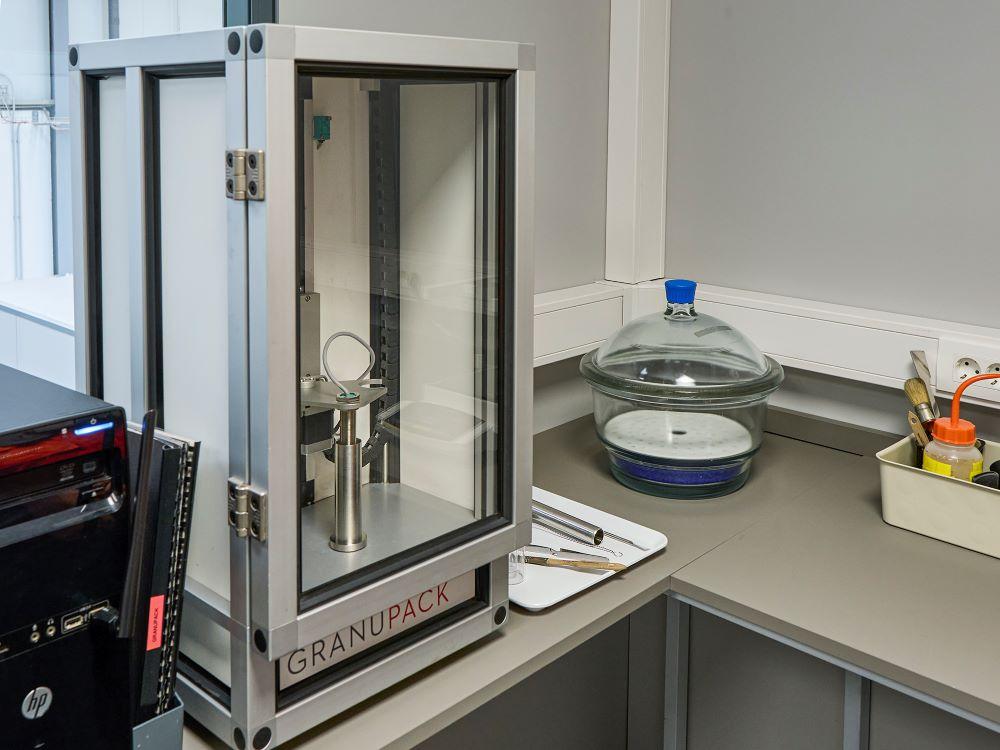

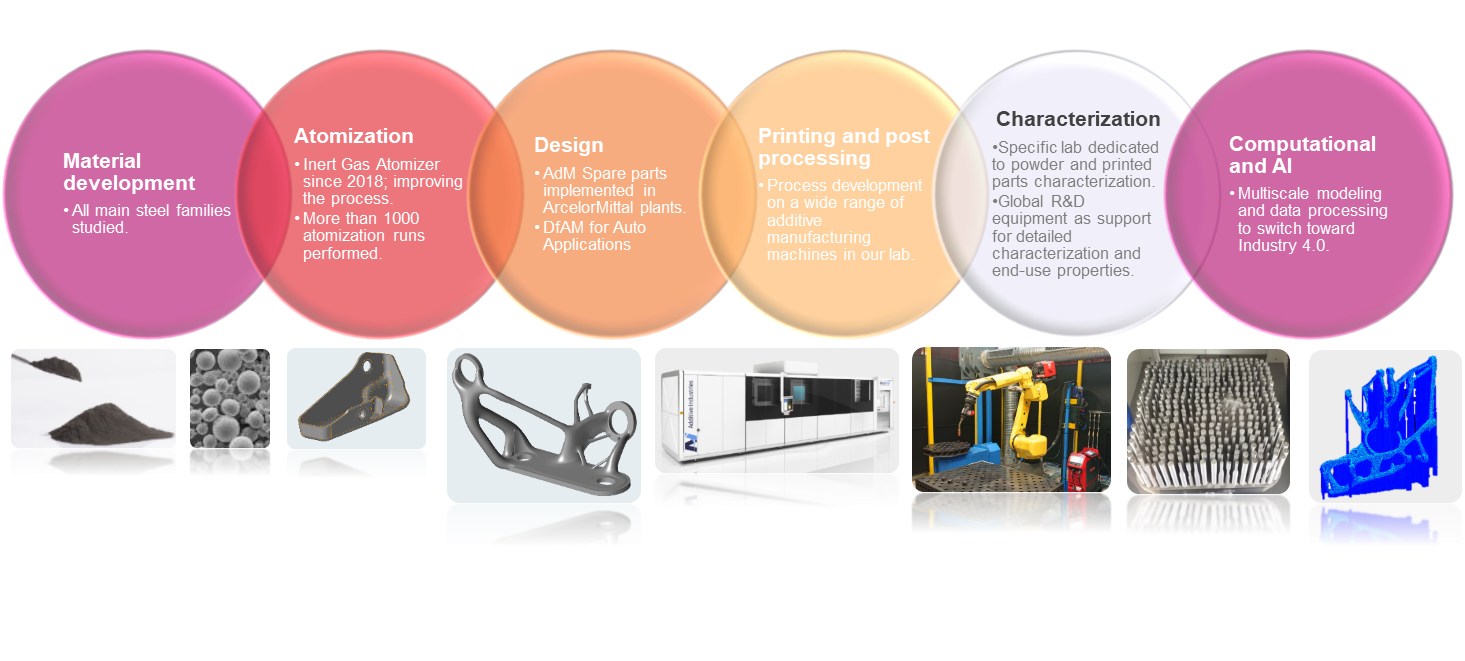

ArcelorMittal has been producing Steel Powders in a pilot atomiser at its Additive Manufacturing lab in Avilés since 2018. With its dedicated R&D facilities and over 50 full-time researchers, we have developed a detailed understanding of the interactions between steel alloy design, atomisation parameters, Additive Manufacturing process parameters and the final properties of the printed parts.

ArcelorMittal believes that Additive Manufacturing can create new opportunities for all manufacturing industries, by enabling the production of complex, customised parts with enhanced properties while simultaneously reducing material waste. With our participation in the Additive Manufacturing market and, mirroring our successful approach with our S-in motion ® programme in the automotive sector, we intend to scale our Steel Powders offering in collaboration with customers and industrial partners, through co-design and co-engineering projects.

Need advise?

Contact our experts to find out how we can help you choose the material that best suits your production needs.