Medical

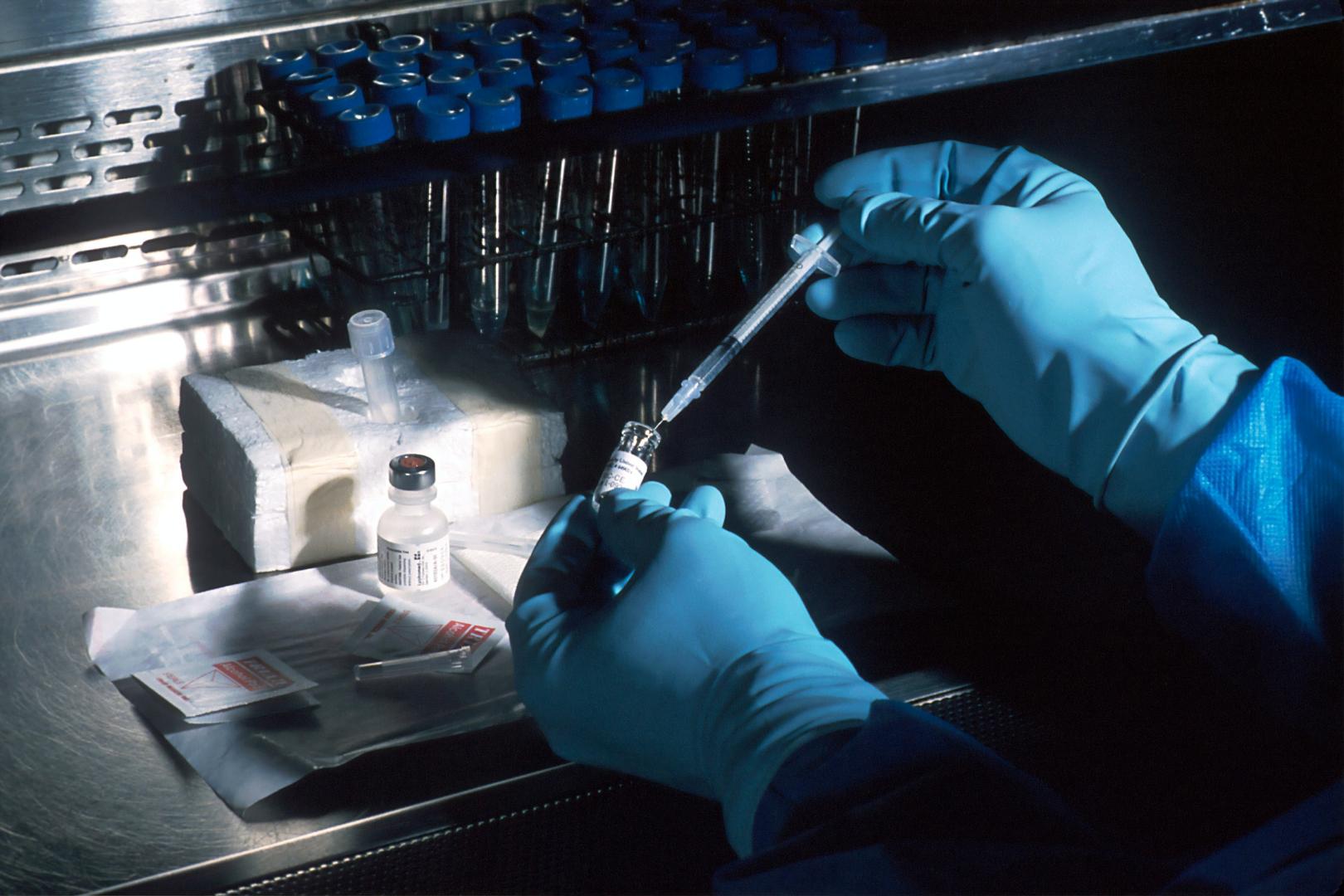

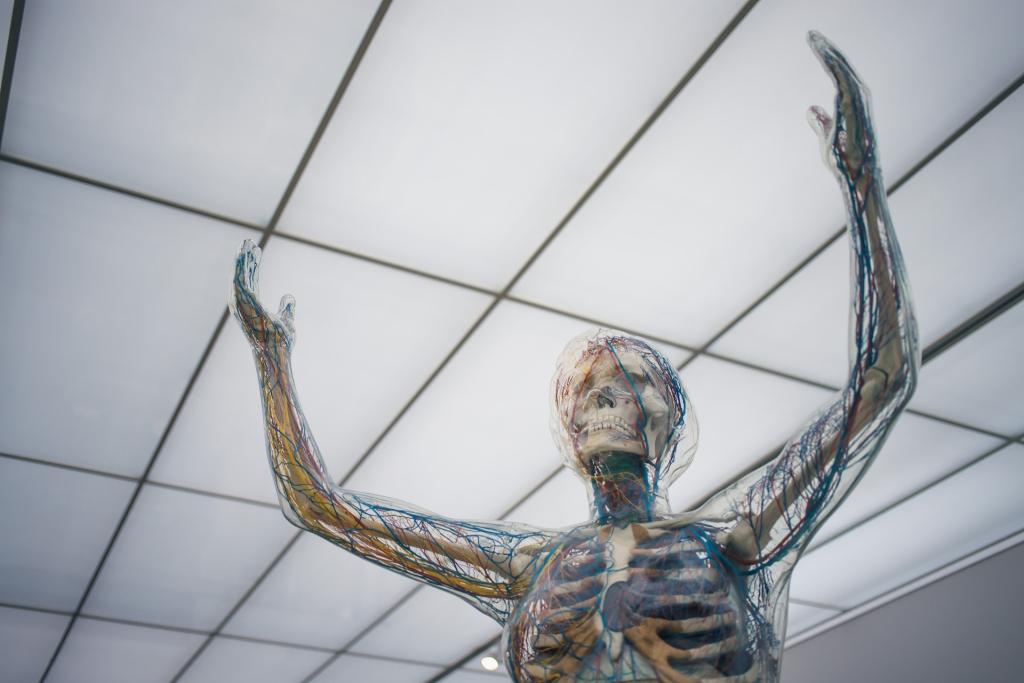

From patient-specific implants, such as cranial and orthopedic implants, and dental restorations, to the production of new instruments, Additive Manufacturing puts the patient at the center thanks to the ability of 3D printing to produce complex and customized objects. This is also affecting the industry by creating new business opportunities alongside technology centers, tooling machine companies, robotic integrators, academia, and industry.

The use of Additive Manufacturing in the medical industry has the potential to drive the future of healthcare. For example, it can enable the production of patient-specific complex, customized medical devices and solutions, which can improve the fit and function of the final product. This can lead to better patient outcomes and a reduction in surgical complications. In addition, costs and lead times can be reduced to produce medical devices with better fit and function, reduced surgical complications, and decreased costs and lead time.

The potential for improved patient outcomes and the development of new business opportunities in the healthcare industry make Additive Manufacturing a key player in shaping its future.

Contact our sales team

Talk to our experts to find out how ArcelorMittal can help you improve your Additive Manufacturing experience in the Defense & Military industry.