Amsterdam's unique 3D-printed bridge

Using typical industrial robots equipped with purpose-built tools, Dutch company MX3D 3D-printed a fully functional steel pedestrian bridge to cross one of the oldest and most famous canals in Amsterdam: the Oudezijds Achterburgwal.

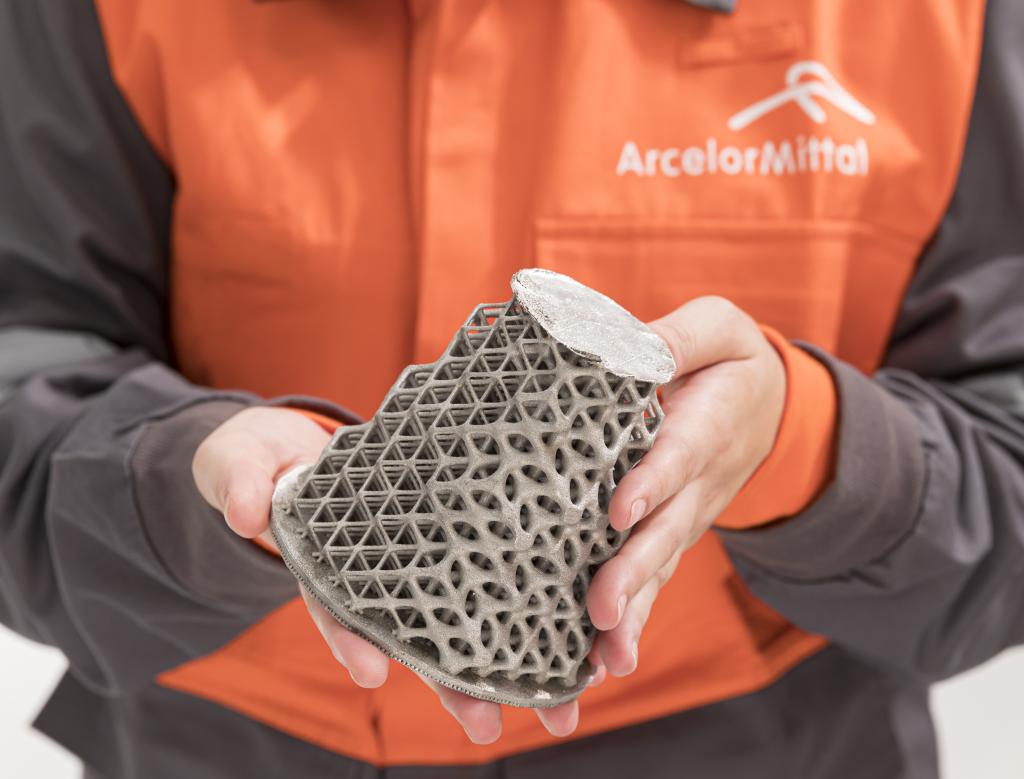

With a unique approach featuring proprietary software, MX3D can use additive manufacturing (also known as 3D printing) to create strong, complex and graceful structures out of steel.

ArcelorMittal’s role is to provide specialized steel wire rods which act as the basic feedstock for the additive manufacturing process, and to provide the necessary metallurgical expertise. The bridge is designed by Joris Laarman Lab wit

Our research centre in Gandrange, France, which is dedicated to R&D activity around long products such as bars and wires, is closely involved in the partnership and has worked on the bridge design from the material point of view, analysing structural behaviour and corrosion properties. A core objective for ArcelorMittal is to better understand the impact of additive manufacturing on steel products so that, for example, we can develop new steel grades that are designed specifically for this specialised use.

Steel Powders are used in multiple industries and applications

Contact our experts to know how ArcelorMittal Powders can help you boost your productivity!

25 February 2022