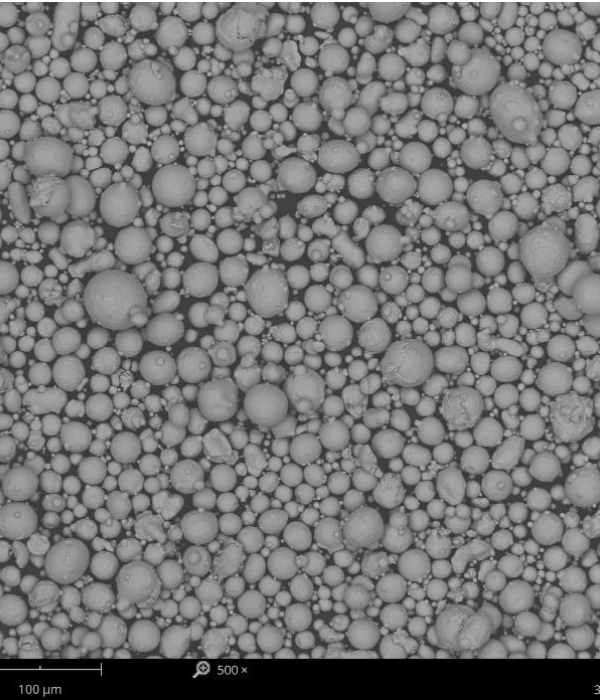

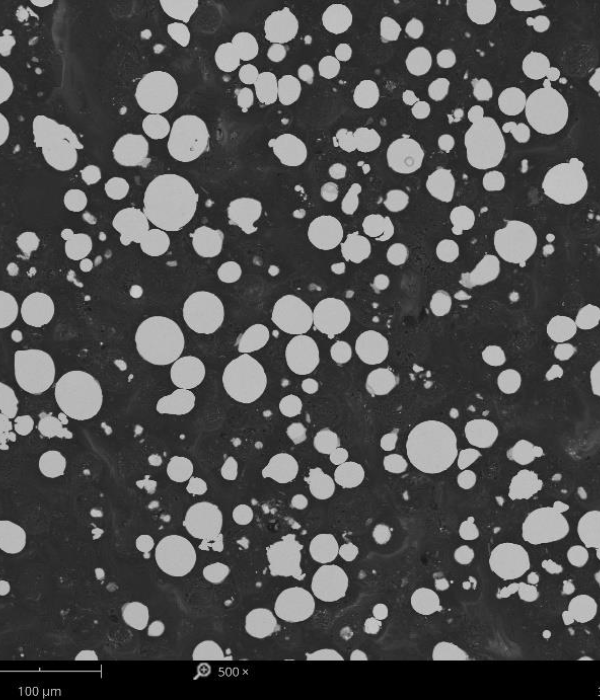

Inert gas atomised Steel Powder. Particle range: 20-53 μm. Net weight: 10 kg.

Our inert gas atomised Steel Powders are made from 100% recycled steel and 100% renewable energy. They are spherical, with high flowability, and low level of impurities.

- The "general purpose" powder suitable for the widest range of applications, across multiple industries

- Used for applications requiring intergranular corrosion resistance.

- It has excellent weldability in laser and electron-beam Additive Manufacturing processes.

Need more quantities or other options ?

AdamIQ™ 316L datasheet

A robust feedstock for any laser powder bed fusion machine (L-PBF).

Chemical Composition in weight %

| Iron | Balance |

|---|---|

| Carbon | < 0.03 |

| Sulfur | < 0.030 |

| Nitrogen | < 0.10 |

| Oxygen | < 0.10 |

| Chrome | 16.00-18.00 |

| Nickel | 10.00-14.00 |

| Molybdenum | 2.00-3.00 |

| Manganese | < 2.00 |

| Phosphorus | < 0.045 |

| Silicon | < 0.75 |

| Nominal particle range | 20.53 μm |

|---|---|

| Apparent density (1) | 4.1 g/cm3 |

| Top density (2) | 5 g/cm3 |

| Hall flow (3) | 15 s/50g |

Inert gas atomised Stainless Steel Powder, it comprises chromium, nickel, and molybdenum with an austenitic microstructure, which is particularly used for applications requiring intergranular corrosion resistance. It has excellent weldability in laser and electron-beam additive manufacturing processes. Solution annealing can improve its corrosion resistance. Most situations do not require solution annealing, which is application specific.

Post-processing methods include traditional machining, abrasive flow machining, shot peening, grinding, polishing, chemical milling/etching, and others. Parts made from 316L generally have service temperatures of up to 425 °C (800 °F), beyond which chromium carbides precipitate. Maximise your printer’s uptime by keeping it loaded and running with this versatile powder.

Also avaiblable in particle sizes :

• Less than 20 microns for Binder Jetting (BJT), Metal Injection Molding (MIM) or specific processes targeting very thin walls.

• 53-105 microns typically for Electron Beam Melting (EBM, E-PBF) and Laser Metal Deposition (LMD).

• Specific sizing can be considered under conditions.

--

(1) Apparent density according to ASTM 8212

(2) Top dansiy cording to 51s 5527-15150 s653201

(3) Hall Flow according to ASTM 8213

available

available

get a quote

get a quote standards

standards