- The "general purpose" powder suitable for the widest range of applications, across multiple industries

- Used for applications requiring intergranular corrosion resistance.

- It has excellent weldability in laser and electron-beam Additive Manufacturing processes.

Need more quantities or other options ?

AdamIQ™ M300 datasheet

Our M300 maraging steel is the right “tooling purpose” powder for applications that need to balance printability, hardness and toughness.

Chemical Composition in weight %

| Iron | Balance |

|---|---|

| Nickel | 18.00 - 19.00 |

| Cobalt | 8.50 - 9.50 |

| Molybdenum | 4.70 - 5.20 |

| Titanium | 0.50 - 0.80 |

| Manganese | < 0.10 |

| Silicon | < 0.10 |

| Oxygen | < 0.10 |

| Nitrogen | < 0.10 |

| Aluminum | 0.05-0.15 |

| Carbon | < 0.03 |

| Sulphur | < 0.01 |

| Phosphorus | < 0.01 |

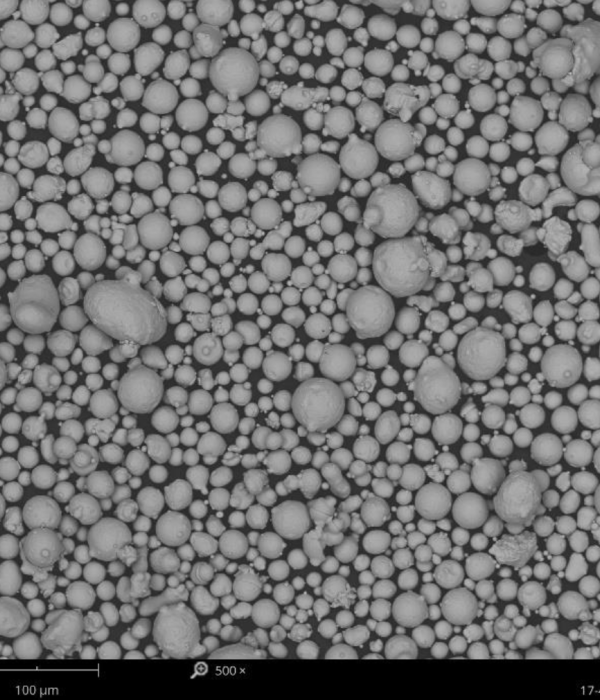

| Nominal particle range | 20.53 μm |

|---|---|

| Apparent density (1) | 4.1 g/cm3 |

| Hall flow (3) | 15 s/50g |

M300 is a maraging steel that offers superior strength, hardness, and toughness, making it an excellent choice for high-performance applications. Its unique strengthening mechanisms, easy heat-treatability, and suitability for additive manufacturing processes make it a top choice for

tooling, molding, aerospace, and automotive components. After undergoing a simple thermal aging heat treatment, the built parts can achieve remarkable characteristics, including hardness higher than 50 HRC and yield strength around 2.000 MPa with excellent toughness. Moreover, the material boasts exceptional machinability to achieve required tolerances and finish. It can maintain its outstanding features even when exposed to mildly elevated temperatures of up to approximately 400 °C (752 °F).

Also avaiblable in particle sizes :

• Less than 20 microns for Binder Jetting (BJT), Metal Injection Molding (MIM) or specific processes targeting very thin walls.

• 53-105 microns typically for Electron Beam Melting (EBM, E-PBF) and Laser Metal Deposition (LMD).

• Specific sizing can be considered under conditions.

--

(1) Apparent density according to ASTM 8212

(2) Top dansiy cording to 51s 5527-15150 s653201

(3) Hall Flow according to ASTM 8213

available

available

get a quote

get a quote standards

standards