University / R&D Centers

Steel Powders for Research

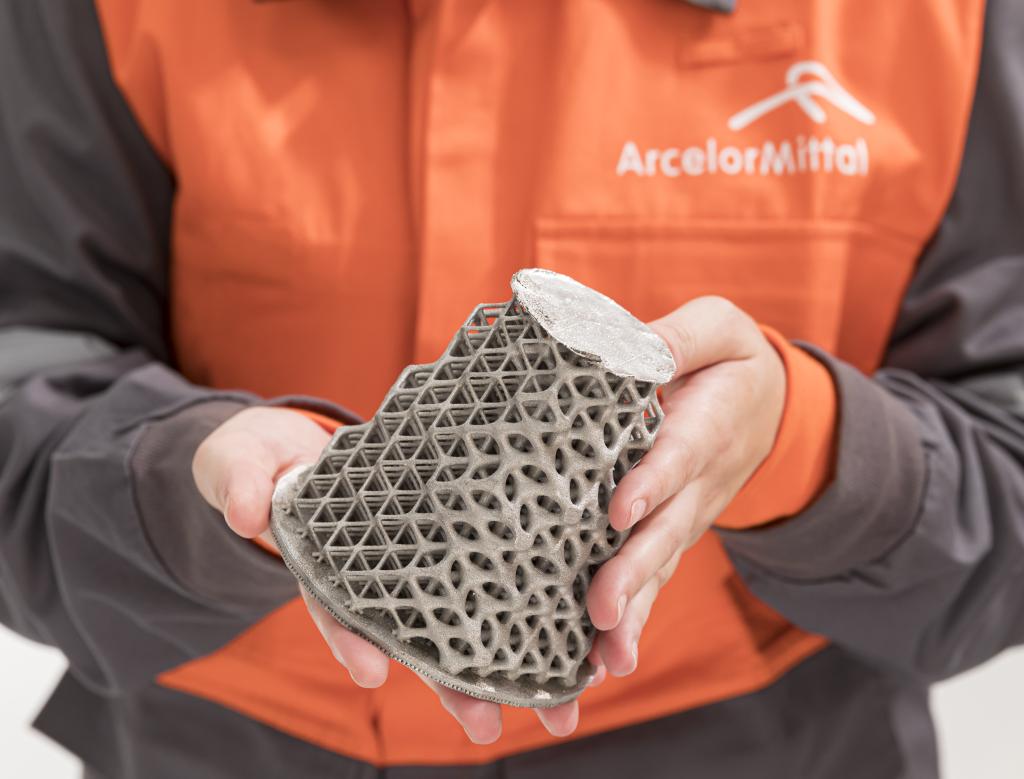

In recent years, many Universities have created Additive Manufacturing Research Groups, in which students and future engineers experiment with the possibilities offered by this technology. At ArcelorMittal Powders we know how important these studies are to advance faster and reach all industries. In fact at ArcelorMittal, through the Global R&D department, we actively collaborate with numerous academic institutions. Proof of this are the initiatives launched with, for example, Nebrija University, in Spain, a collaboration from which projects such as the use of 3D to build a motorbike chassis or the application of Steel 3D printing technology in a Dakar Rally vehicle.

We can help you in your research!

Contact us if you are working on Additive Manufacturing in a University or R&D center.