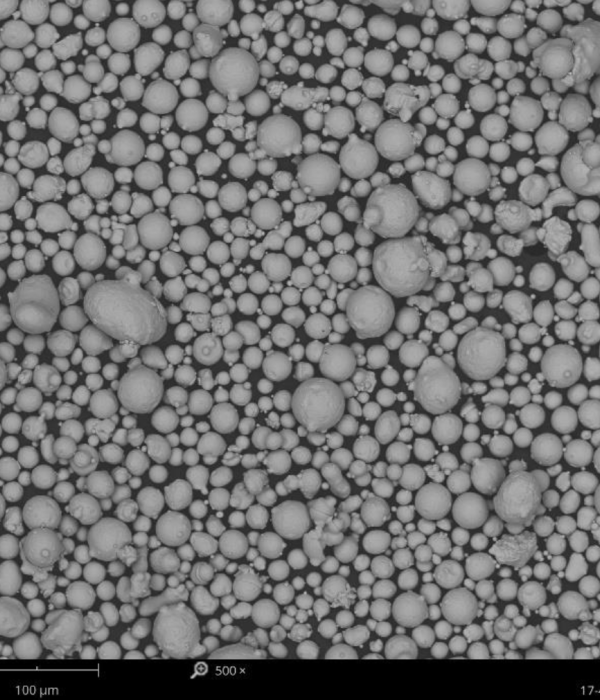

Inert gas atomised Steel Powder. Particle range: 20-53 μm. Net weight: 10 kg.

- The "general purpose" powder suitable for the widest range of applications, across multiple industries

- Used for applications requiring intergranular corrosion resistance.

- It has excellent weldability in laser and electron-beam Additive Manufacturing processes.

Need more quantities or other options ?

AdamIQ™ 17-4PH datasheet

Premium stainless-steel powder, AdamIQ™ 17-4PH offers high strength and durability with excellent corrosion resistance.

Chemical Composition in weight %

| Iron | Balance |

|---|---|

| Chromium | 15.00 - 17.50 |

| Nickel | 3.00 - 5.00 |

| Copper | 3.00 - 5.00 |

| Niobium + Tantalum | 0.15-0.45 |

| Manganese | < 1.00 |

| Silicon | < 1.00 |

| Nitrogen | < 0.10 |

| Oxygen | < 0.10 |

| Phosphorus | < 0.04 |

| Carbon | < 0.07 |

| Nominal particle range | 20.53 μm |

|---|---|

| Apparent density (1) | 4.1 g/cm3 |

| Hall flow (3) | 15 s/50g |

This great blend of properties makes it an excellent candidate for the widest possible range of applications, especially at elevated in-use-temperatures, up to 300°C (572°F), including rapid tooling functional components in nearly every market. Additionally, 17-4 PH is widely used in environments where a level of corrosion resistance comparable to that of the austenitic grades is needed, but in applications that require higher strength and hardness than the austenitic grades can provide.

A version that meets aerospace standard is available.

Also avaiblable in particle sizes :

• Less than 20 microns for Binder Jetting (BJT), Metal Injection Molding (MIM) or specific processes targeting very thin walls.

• 53-105 microns typically for Electron Beam Melting (EBM, E-PBF) and Laser Metal Deposition (LMD).

• Specific sizing can be considered under conditions.

--

(1) Apparent density according to ASTM 8212

(2) Top dansiy cording to 51s 5527-15150 s653201

(3) Hall Flow according to ASTM 8213

available

available

get a quote

get a quote standards

standards